View Past Projects

With over a thousand completed jobs since June of 2000 True North has a wide base of experience with many different customers.

Our customers come from a variety of industries. Injection molding, packaging, medical, lighting, metal forming, tire processing, roll forming equipment, among others. Below are a few examples of projects that showcase our unique abilities.

Example 1

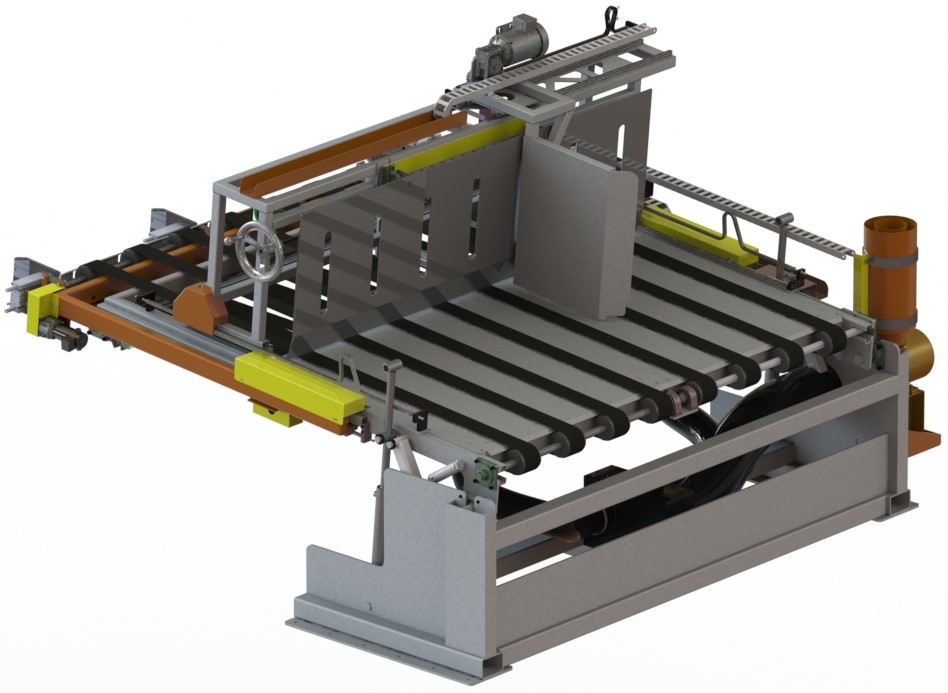

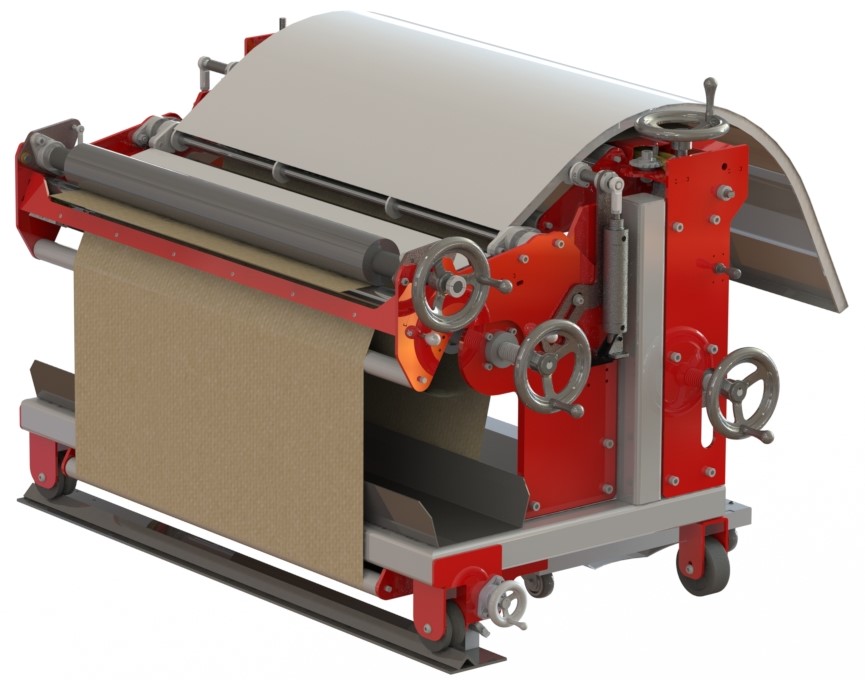

Corrugated Preefeder

Designed primarily by Brad Lanser, this machine is part of a family of corrugated cardboard machines. Using belts, hydraulics, and acme screws to adjust stacking height and sheet width, this machine can handle all of the major sizes of cardboard used by the customer.

Example 2

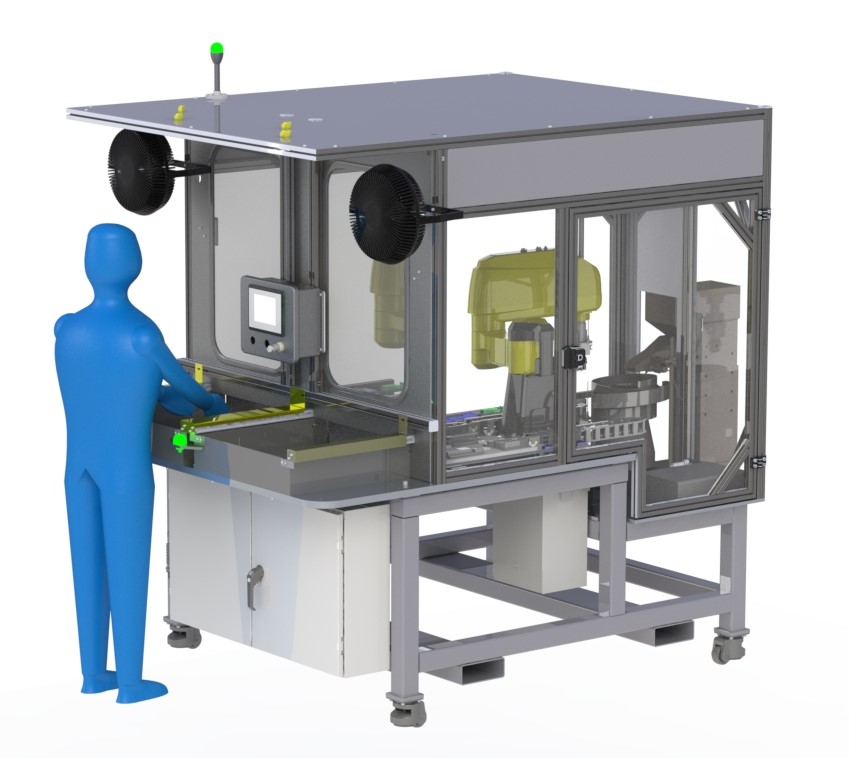

Robotic Clip Install Machine

This machine was designed and built to install clips onto a variety of automotive parts within a short amount of time. With a bowl feeder and Fanuc arm, parts loaded onto a selected nest by an operator come out of the machine ready for install. Light curtains, electromagnets, and a variety of sensors work to catch faulty parts and keep the operators safe.

Example 3

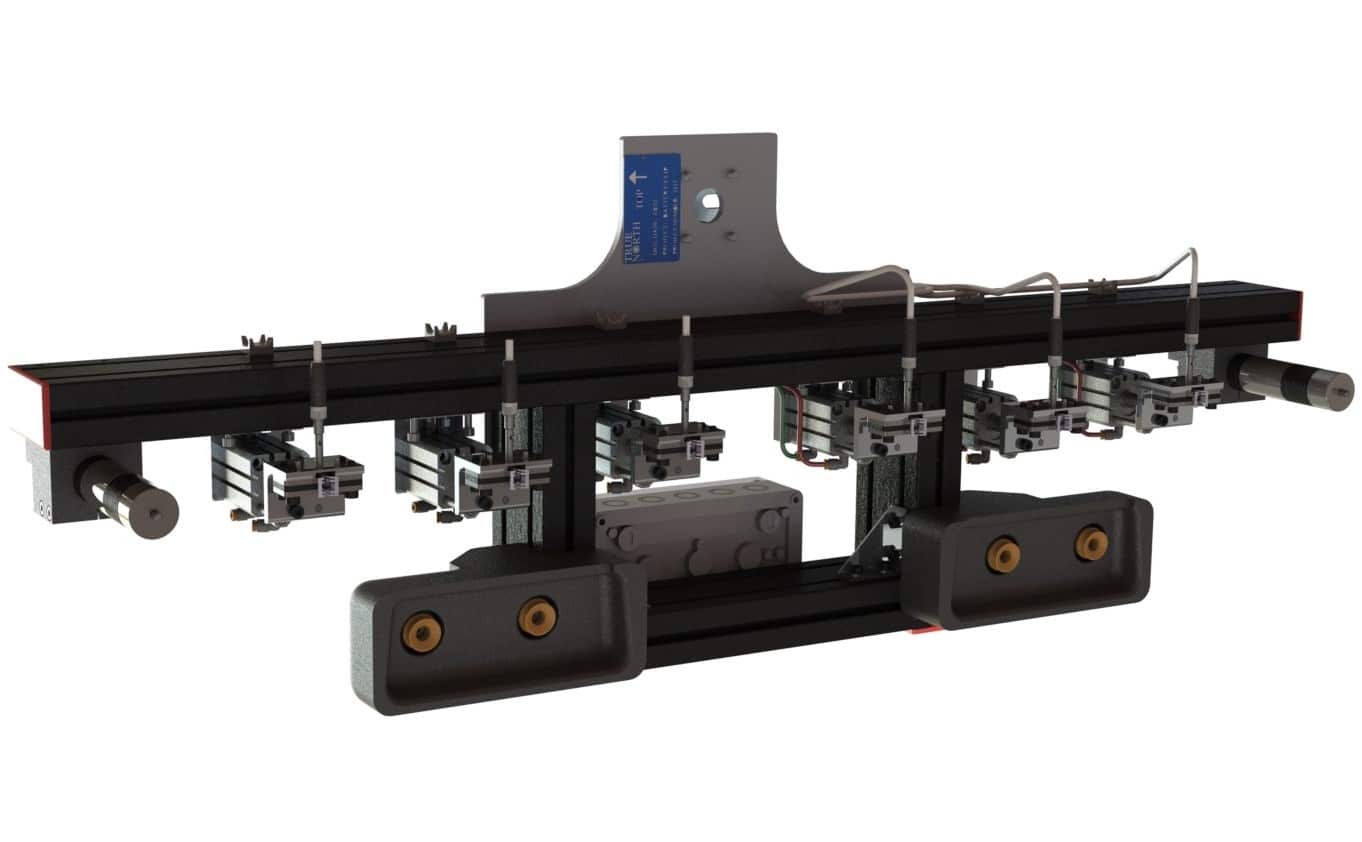

Injection Molding: EOATS and mold tending

True North has decades of experience designing high quality and very precise robotic End of Arm Tools (EOATs). At True North, we employ high quality 3D printed parts along with other technologies for quick turn around and high accuracy. True North is familiar with creating complex EOATS capable of operations such as part bending, clip installation, and insert placement.

Example 4

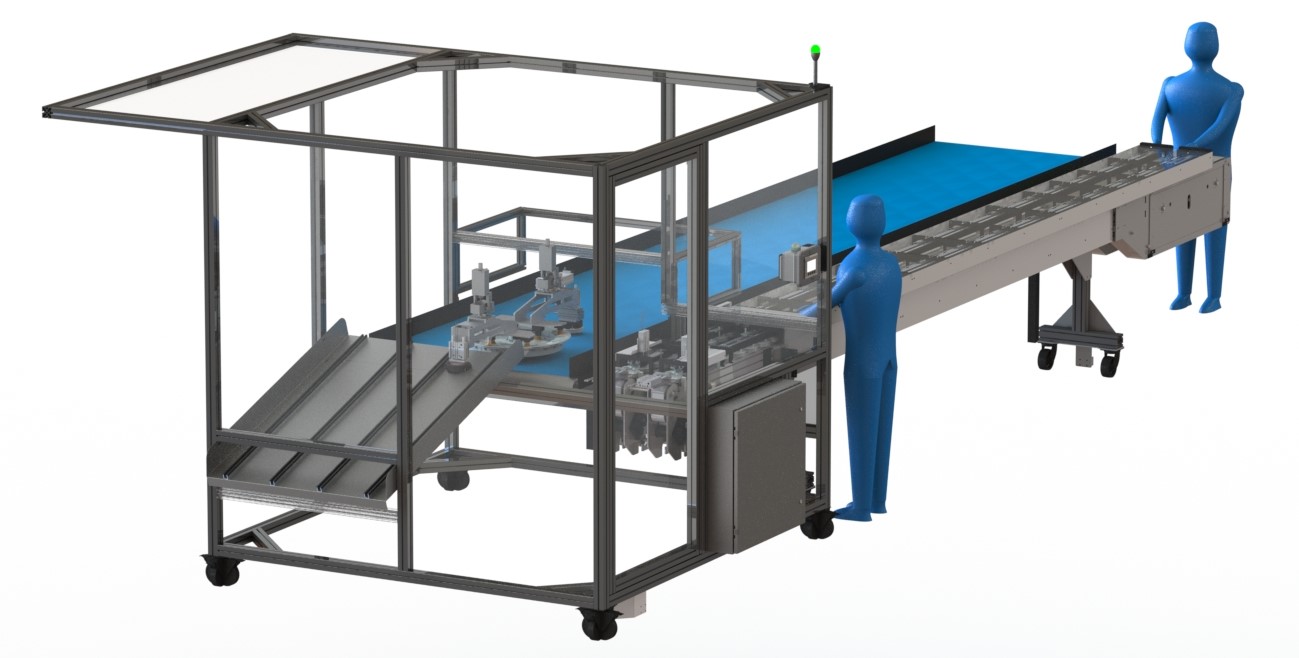

Tire Production Lines

Designed primarily by Ben Casey for a local tire producer, this family of machines assists in automated movement of tires, trimming of vents after the tire re-tread process, and cleaning of wheel rims before tires are added. Some of these machines are designed to be totally automated, manually operated, or some to be controlled by either. These machines were designed to produce higher quality products at faster cycle times than the existing systems.

Example 5

Casted Insert Conveyor

This conveyor machine was designed by Mark Lanser and presented die cast inserts in the proper orientation so that the mold tending robot could pick them with EOAT’s and load them into a large 1100 molding machine. An accumulation conveyor allows for operators to pre-load inserts as the mold continously runs.

Example 6

Felt Applicator

Our customer hired us to design a machine that they intended to sell as an add-on machine to existing roll forming machines. True North worked with our customer to design the initial machine and continue to maintain the design as revisions and improvements occur. The machine is considered a product for our customer and True North helps to manage the design for them.

Creating solutions for you. Get your free consultation.